Unique, cross-disciplinary blend of process and robotic automation for high speed, accurate bagging. Gravity and fine screw feeding for precise filling. In-built features for bag handling, material flow, and stitching ensure continuous operation with packaged product integrity.

Cybernetik Bagging Machines

CorePack

Up to 4 bags/min

Entry model open mouth bagging machine suitable for low production rate and with quick ROI.

- Suitable for granules, powders and pellets

- Suitable for high accuracy applications with accuracy < 0.5%

- Hygienic design available for food and pharma applications

- Modular design for future upgrading to automatic variants

- Gross weighing and net weighing options available

AutoPack

Upto 8 bags/min, Single Bag Variant

Electro-pneumatically operated automatic bagging system suitable for mid- level production requirements. Suitable for minimizing manpower and clean/ hazardous applications.

- Suitable for granules, powders and pellets

- Hygienic design and flameproof options available

- Only one operator required for empty stack loading

- Integrates with loss in weight filling system

- Ideal for single bag variant and dimension

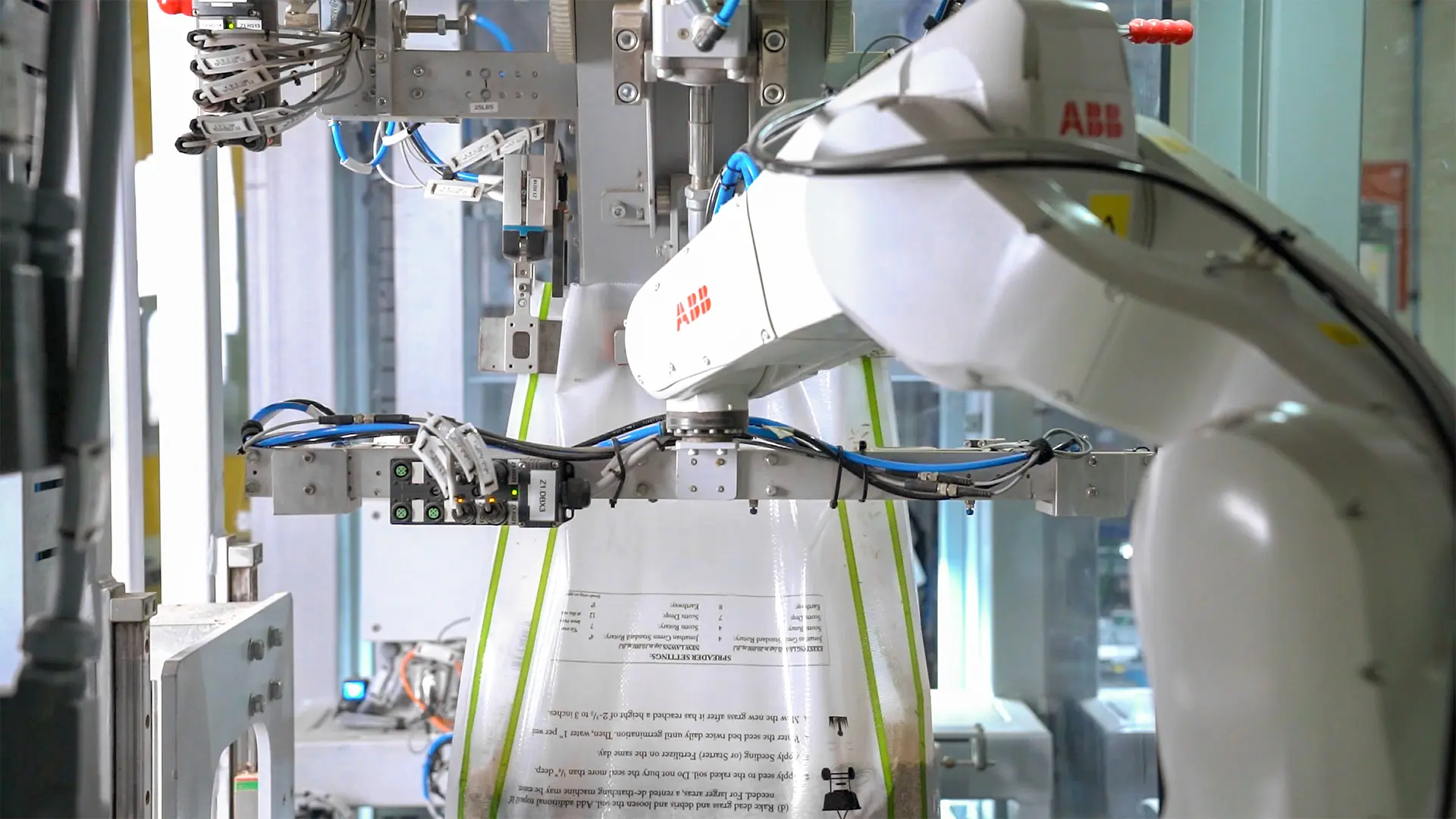

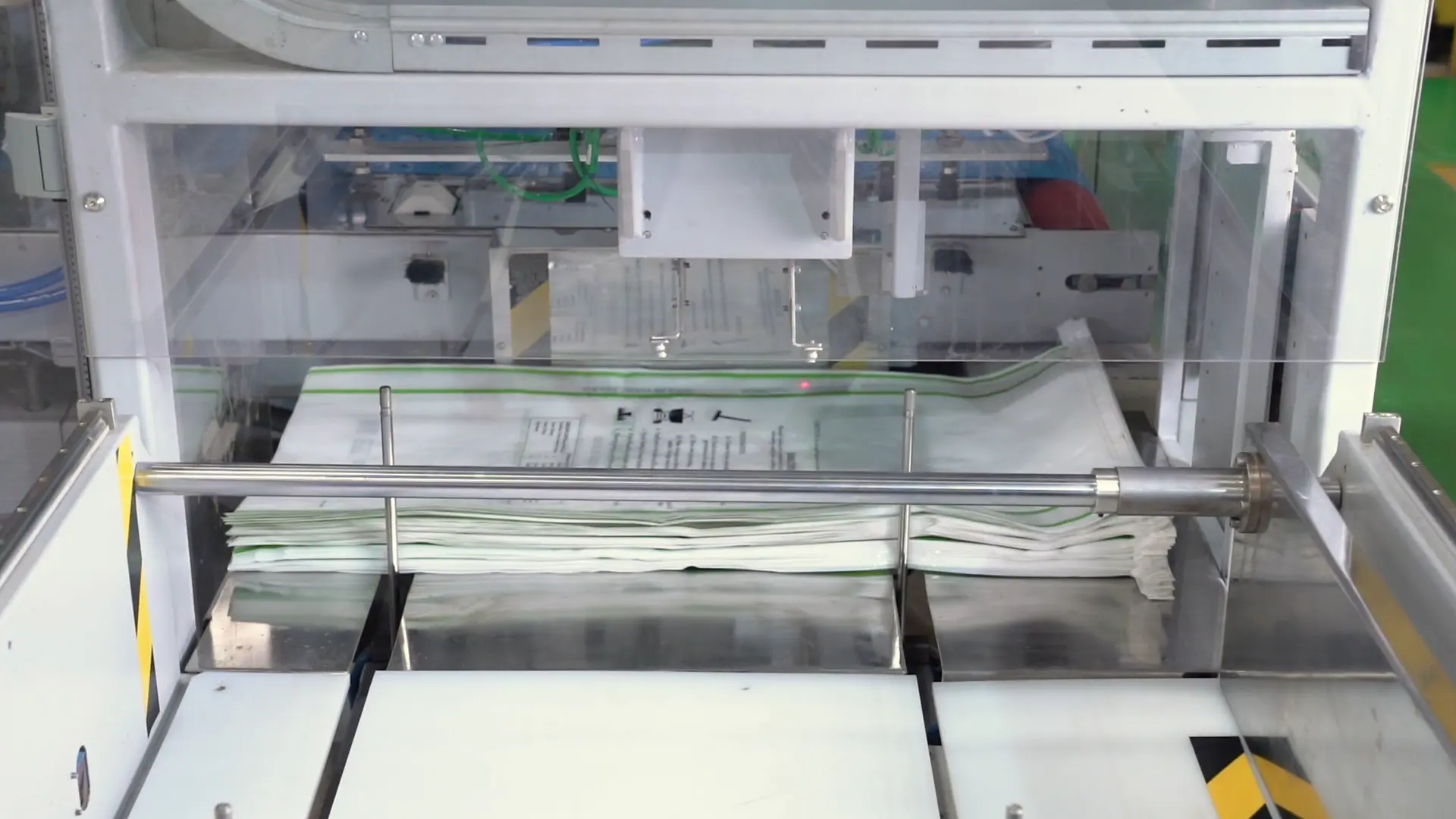

RoboPack 1

Upto 8 bags/min, Multiple Bag Variant

Robopack 1 takes advantage of the flexibility of using robots for handling multiple bag variants with minimal changeover time.

- Suitable for granules, powders and pellets

- 6-axis robot is used for empty bag loading and filled bag transfer

- Quick changeover to handle different bag sizes

- Integrates with loss in weight filling system

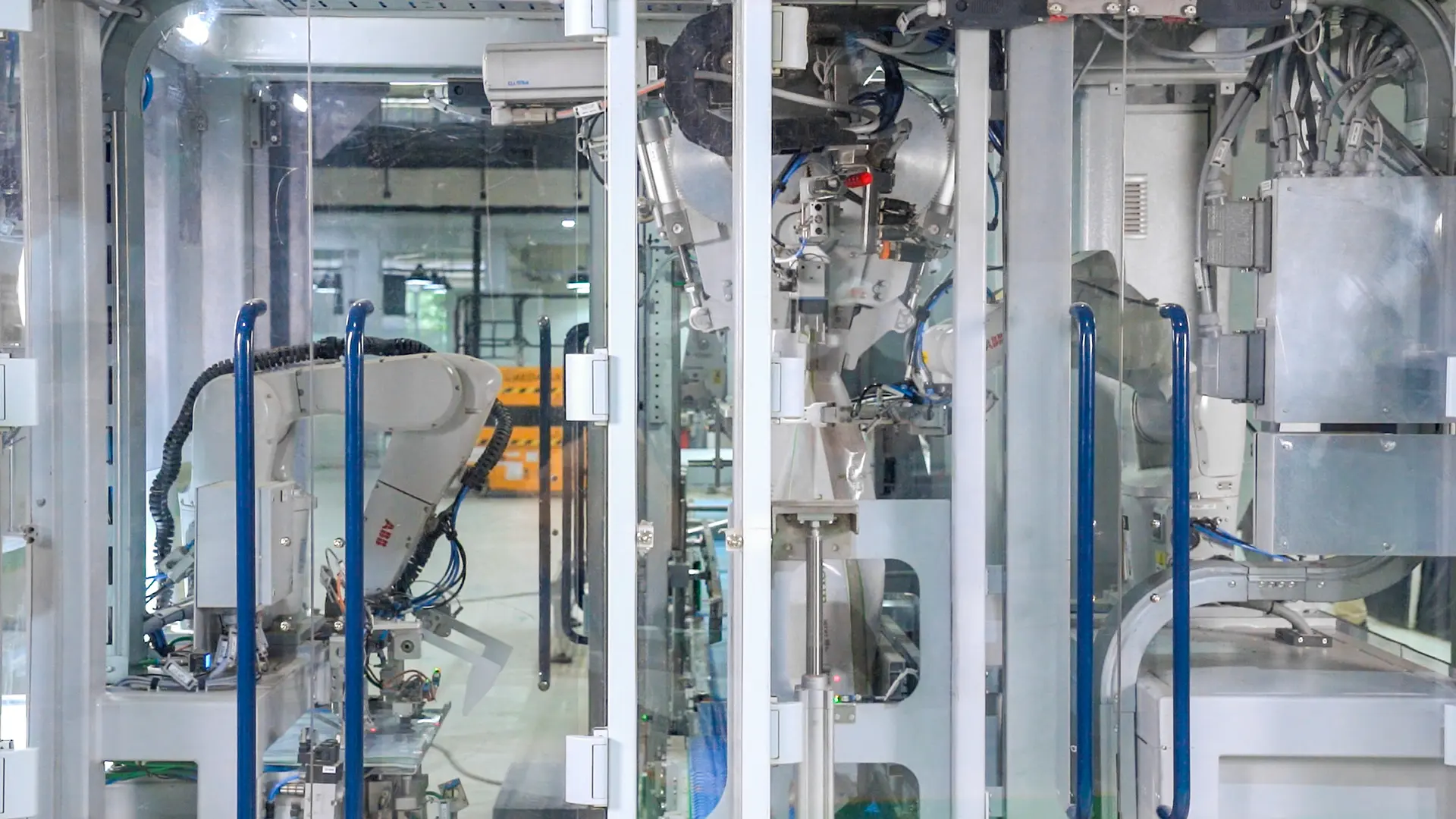

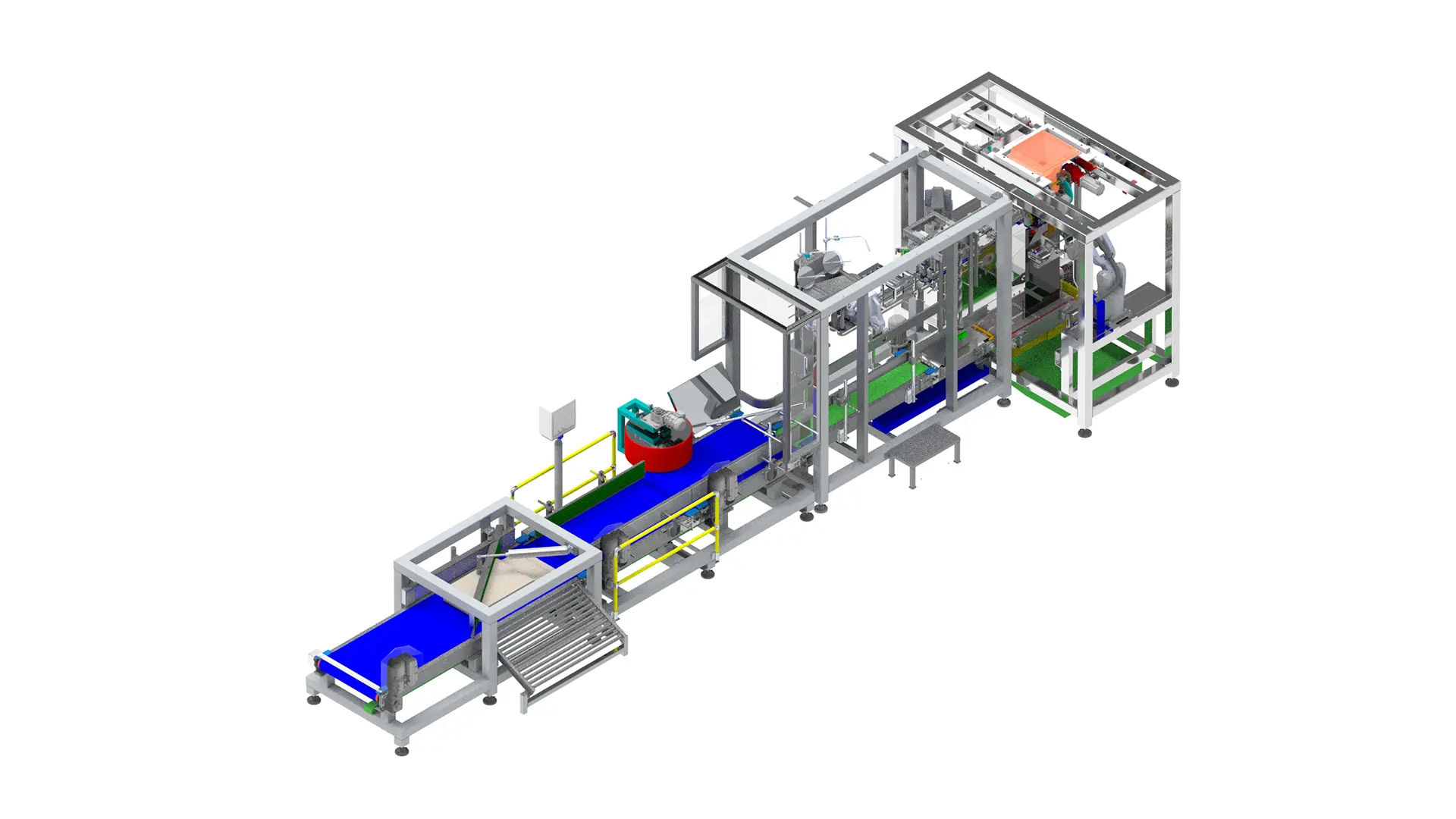

Robopack 2

Upto 15 bags/min

The flagship Robopack 2 model is our high speed fully automatic system, suitable for high throughput applications with minimal manual intervention.

-

Suitable for granules, pellets and powders

(Capacity may vary based on powder properties) - Fully modular plug and play design with no robot training required

- Integrates with a dual loss in weight filling system for maximizing throughput

High Speed Bagging Machine

Products Handled

GRAINS

GRANULES

FLAKES

PELLETS

AGGREGATES

SEEDS

Bag Sizes

10 KG BAG

25 KG BAG

50 KG BAG

Bag Type

Paper

PE

Laminated & Non-Laminated Woven PP

HDPE

PPE

Know more about our bagging machine solutions.

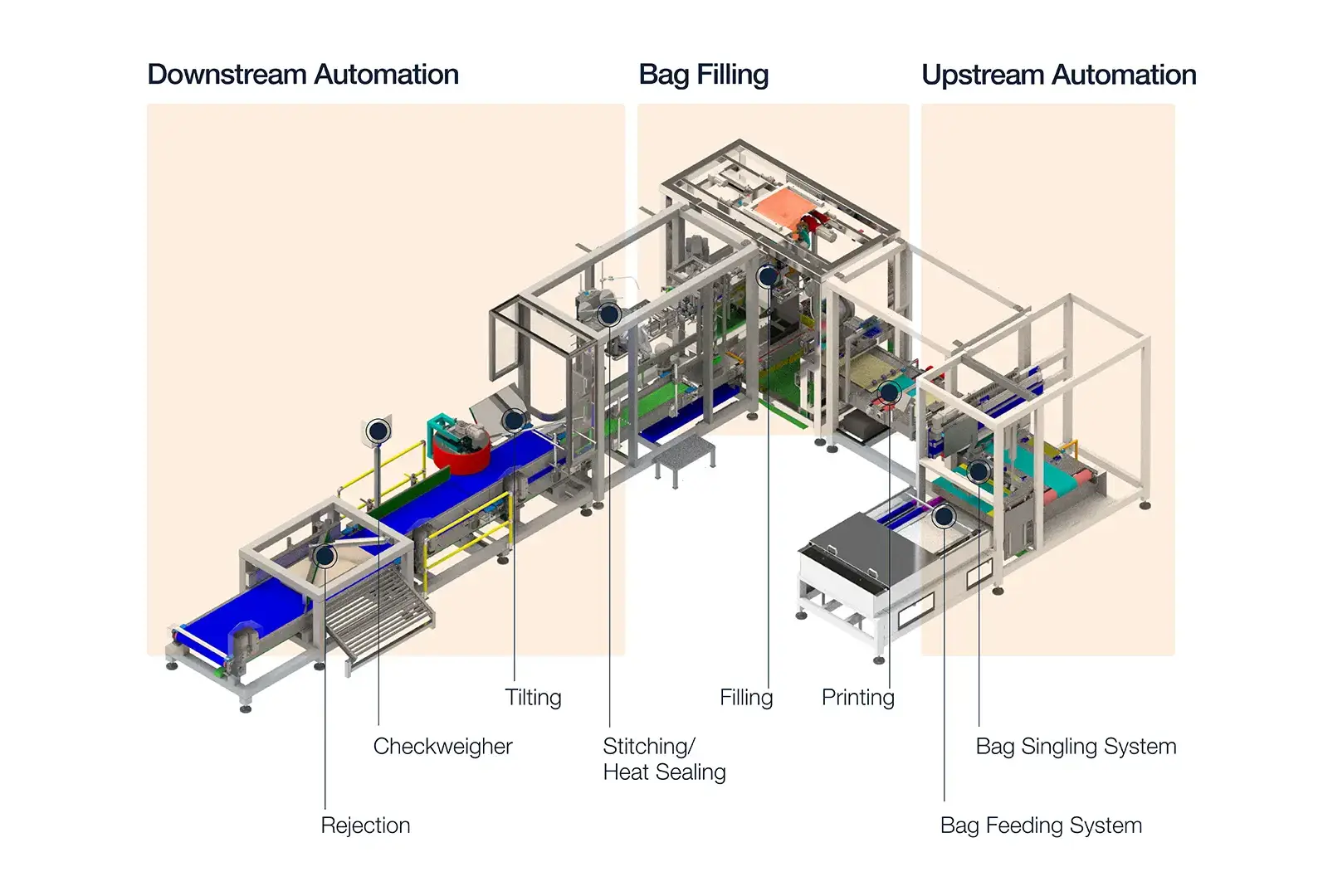

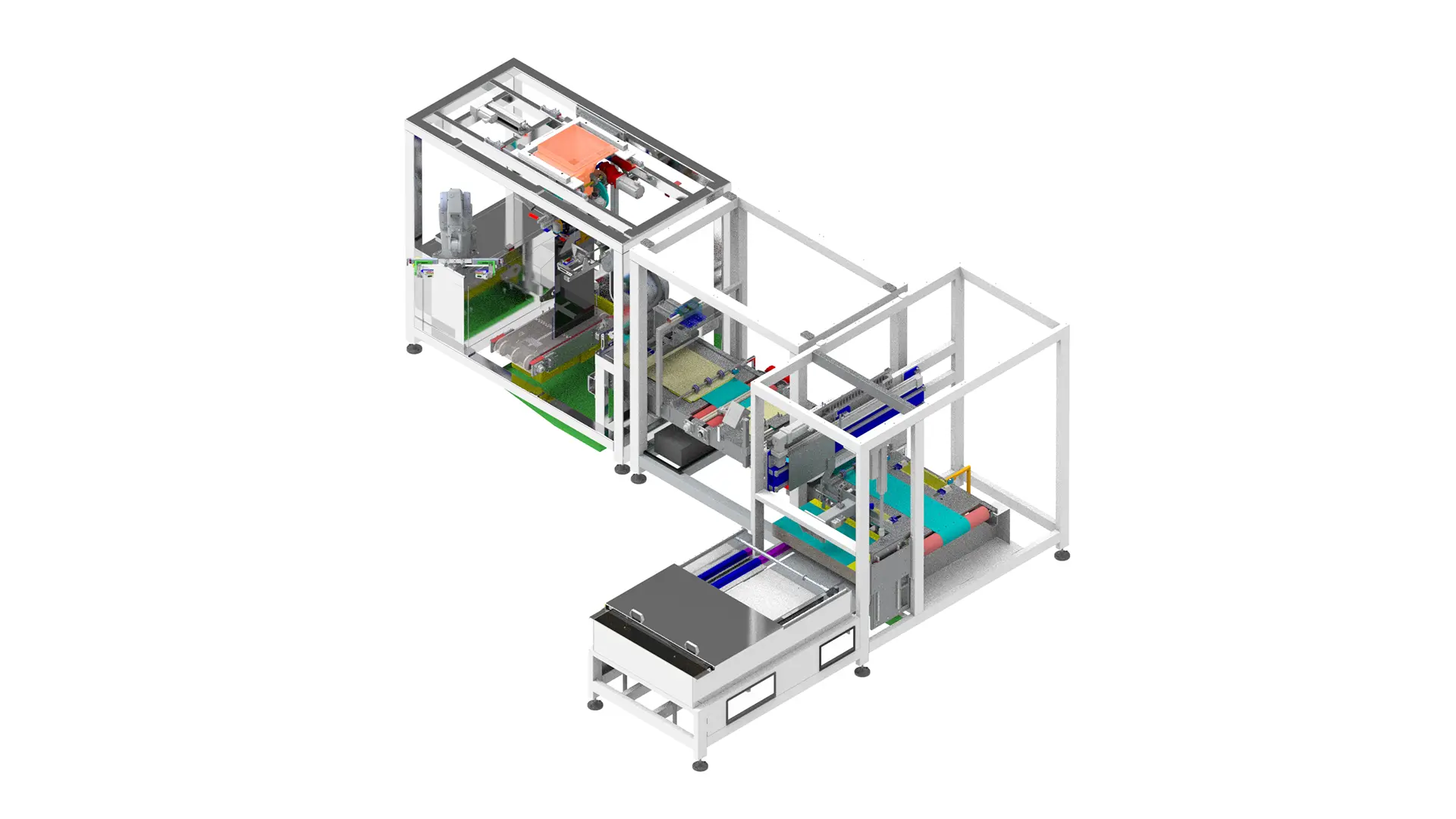

Upstream Automation

Bag Feeding System

- Bag stack infeed system

- Pneumatic indexer for bag feeding

- Quick changeover for different bag sizes

Bag Singling System

- Servo driven bag singling system

- Pneumatic grippers for bag clamping Bag centering system after placing

- No changeover required for different bag variants

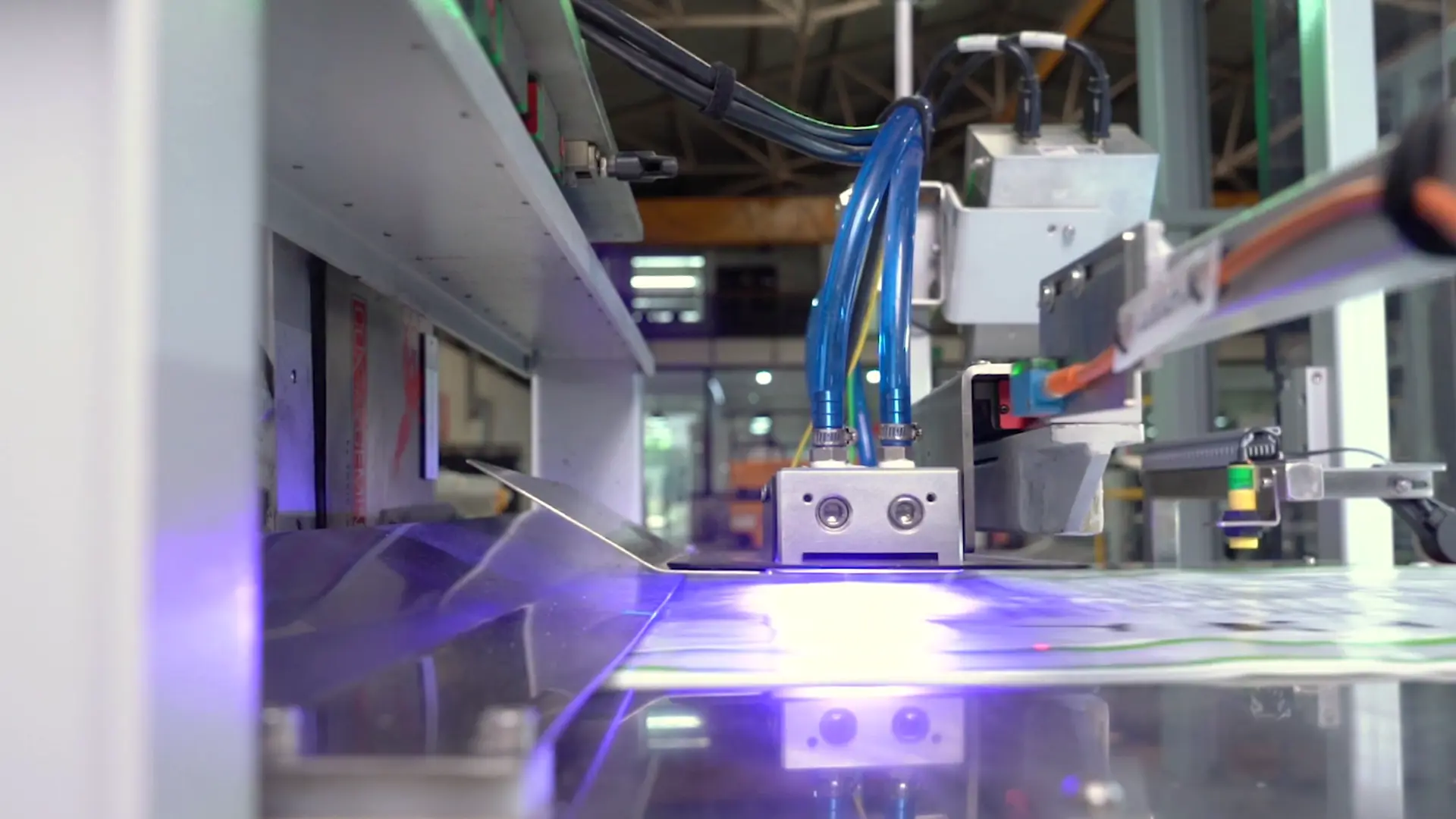

Printing

- Printing for printing batch/date code

- Inkjet/Laser options available based on bag/print details

- UV curing options available to minimize drying time

- Recipe based system for different bag recipes and batch recipes

Downstream Automation

Stitching

- Inline stitching for bag closing

- Vertical axis for automatically setting stitching height

- Stitching pitch can be set for ensuring optimal closing

Tilting

- Tilting system for laying bags horizontally

- Cam based system for ease of use

Checkweigher

- Inline checkweigher for weighing individual bags

- Recipe based system for handling

- High accuracy options available for minimizing weight tolerance

Rejection

- Pneumatic pusher based rejection

- Gentle rejection to eliminate bag damage

- Idler rollers for controlling bag drop

Sealing

- Ultrasonic/Heat sealing options available

- Based on bag material, suitable sealing can be selected

- Suitable for fine powders to eliminate

Bag Flattener

- Bag flattener options available for ensuring flatness

- Suitable when integrated with palletizers

Complete Your Process with End-of-Line Automation

Bag Palletizer

Streamline your production right through to dispatch with fully automated bag palletizing systems. Designed for speed, precision, and gentle handling, our palletizers neatly stack bags in stable, optimized patterns for safe transport and easy storage. Integrated with your bagging line, they minimize manual handling, reduce labor costs, and ensure consistent load quality - keeping your operation efficient from fill to shipment.

Speed: Up to 10 bags/min (Customizable)

Models

| Parameters | CorePack | AutoPack | RoboPack 1 | RoboPack 2 | |

|---|---|---|---|---|---|

| Bag Filling | Type | Semi-automatic | Automatic (no robot) | Robot (1 arm) | Robot (2 arms) |

|

Speed *depends on product material and trials |

2–5 bags/min | 6–8 bags/min | 12 bags/min | 15–20 bags/min | |

| Description | Entry-level, basic machine | Suitable for mid-sized ops | High performance | Flagship model, max automation | |

| Typical Bag Sizes | Multiple bag sizes possible | Single bag size | Multiple bag sizes possible | Multiple bag sizes possible | |

| Typical Bag Weights | 10–50 kg | 10–50 kg | 10–50 kg | 10–50 kg | |

| Bag Types |

Paper, PE, Laminated and Non-laminated Woven PP, HDPE, PPE |

Paper, PE, Laminated and Non-laminated Woven PP, HDPE, PPE |

Paper, PE, Laminated and Non-laminated Woven PP, HDPE, PPE |

Paper, PE, Laminated and Non-laminated Woven PP, HDPE, PPE |

|

| Products | Granules, pellets, powders | Granules, pellets, powders | Granules, pellets, powders | Granules, pellets, powders (free-flowing) | |

| Upstream | Bag Feeding | Not required | Required | Required | Required |

| Bag Singling | Not required | Required | Required | Required | |

| Printing | Optional | Optional | Optional | Optional | |

| Downstream | Stitching | Optional | Optional | Optional | Optional |

| Tilting | Optional | Required | Required | Required | |

| Checkweigher | Optional | Optional | Optional | Optional | |

| Rejection | Yes, if checkweighing is done | Yes, if checkweighing is done | Yes, if checkweighing is done | Yes, if checkweighing is done | |

| Sealing | Optional | Optional | Optional | Optional | |

| Flattening | Optional | Optional | Optional | Optional | |

| Add-on | Feeding Silo | Optional | Recommended | Recommended | Recommended |

| Weigh-fill System | Recommended | Recommended | Recommended | Recommended | |

| Robotic Palletizing | Not required | Optional | Optional | Optional |

Certifications

0+

Systems Installed Worldwide

0+

Satisfied Customers